Multi Slab Brace Formwork

Say goodbye to timber pegs, lumber kickers, walers and nails. The future is here.

MSB Form is an adjustable formwork solution for the concrete construction industry, designed to be compact, lightweight, and strong for all conditions and applications - commercial, industrial, residential and civil.

If you want to get the job done faster, safer and greener, ensuring a superior finished result - upgrade to MSB Form. Don’t get left behind.

MSB Form is made of the highest quality zinc-plated steel and is designed to be lightweight, compact and extremely strong for all conditions. You can expect maximum results throughout the slab process, whether you’re using MSB Form for slab on grade, fixing down to concrete or plywood. Improve efficiency and safety, reduce labour and consumables ensuring a cost-effective business model with our adjustable concrete forms.

MSB Produces 5 varieties of Adjustable Form Braces that can be used together or separately to achieve many concrete forming needs.

A, B, C FRAMES

Perfect for conventional slabs and monolithic slabs

Ideal for 310mm and 385mm waffle / 6” - 15” slab on grade

Frames connect and stack up to 1.2m / 4 ft tall

Can be fixed to concrete, plywood and ground

Use for:

Brick ledge / rebate, curbs, slab-on-grade, monolithic slabs, paving, radius pours, tank pads, tilt-up slabs, turn-down slabs

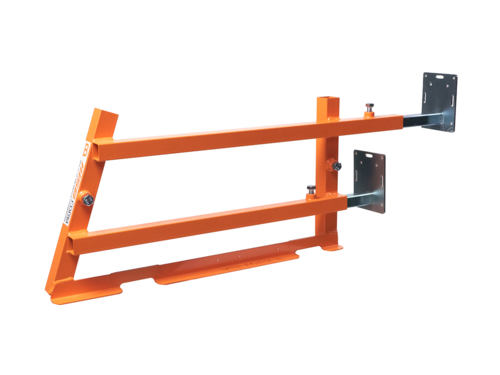

D FRAME

Perfect for tilt panel construction (frame height 175mm / 6.9”), elevated slabs (200mm / 8”) podium deck and more

Arm extends out 28cm / 11”

Can be used with hinge insert (sold separately) - great for bridge decks, ensuring you achieve between 45° - 145° on your edge form.

Can be fixed to concrete, plywood and ground

Use for:

High rises, elevated slabs, slab-on-grade, tilt-wall panels, internal flat floors, external paving up to 250mm / 10”

HIGH RISE FRAME

Ideal for 150mm - 600mm / 6” - 24” elevated slabs

Can be fixed to concrete and plywood

Use for:

Bridge decks, post-tension slabs, elevated slabs, table forms

Features and Benefits

How often will I need to replace my MSB Form braces?

MSB Form can last 10+ years with the right care. Each frame is made using the highest quality steel, then zinc-plated and powder coated, eliminating consumables by minimising wastage. You won’t need to replace these guys for a long time.

What happens when stormwater pipes run parallel closely alongside each slab?

MSB Form is set back from the trench and rebate inserts adjusted up to 300mm (12”) to eliminate damage to pipes.

How are pegs/steel rods removed from the ground and unit?

The system is designed so that anyone can easily pull out the pegs. If you would like to utilise a tool for this, however, we recommend the FatMax FuBar Utility Bar.

What is the best way to transport my MSB Form set?

Your set will fit in any regular truck or trailer. They are designed to stack on top of each other and keep space free for your other equipment

What ground conditions does it work in?

The product is designed to work in any conditions – regular soil, clay, sand, rock, etc.